Transfer Center 5G4KMU

The new mobile technology 5G is the communication standard of the future - in factories as an enabler for Industry 4.0 and the Internet of Things. At the 5G4KMU transfer center, small and medium-sized enterprises have the opportunity to research and further develop products, applications and business models based on 5G.

With 5G as a private network in the factory, the needs of manufacturing companies and the increased requirements of industrial applications are taken into account. This is because 5G enables demand-oriented networking with high bandwidth, low latency and a high number of connections.

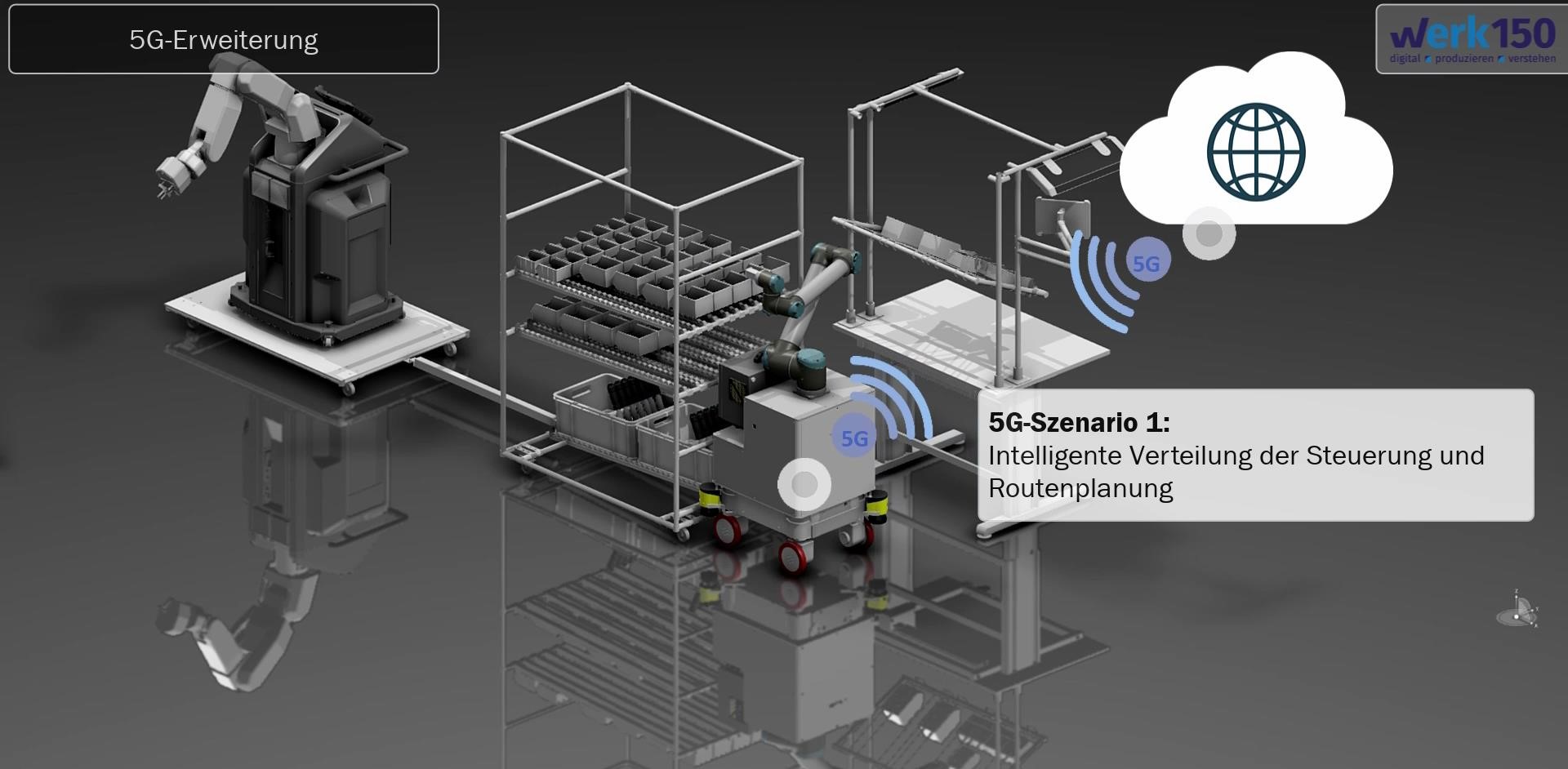

5G thus creates an important basis for Industry 4.0 applications, intelligent mobility and logistics as well as for the Internet of Things. The technology enables the networking of very many end devices (e.g. large sensor networks), provides high data transmission rates for VR and AR applications or image processing and enables new applications through reliable communication and with short delay times (e.g. for machine control and regulation).

In the test environments of the 5G4KMU transfer center, small and medium-sized enterprises (SMEs) can use this technology. At Werk150, a private standalone 5G network with two radioheads, various end devices and expert knowledge on 5G are available. The focus in Reutlingen is on logistical applications (internal and external logistics) and the provision of information in the company.

Forms of cooperation for SMEs

The project is funded by the Ministry of Economic Affairs, Employment and Tourism Baden-Württemberg. Although companies do not receive direct funding in monetary form, expenditures for the test environments / research facilities are subsidised. The company's own contribution is thus limited to the description of the project idea for the application and its detailed communication, as well as cooperation in the quick check or in the joint implementation of the exploring project in a test environment.

Research focuses

As part of the 5G4KMU project, Reutlingen University is researching the feasibility of industrial use cases using 5G campus networks. The primary research question in this context is:

To what extent do the performance parameters and service categories of 5G campus networks enable the fulfilment of the technical requirements of relevant industrial and medical use cases?

The research results are validated in different industrial use cases together with industrial companies from practice. Initial results with a focus on intralogistics applications were published in a scientific paper at the „International Conference on Competitive Manufacturing - COMA22“ in January 2022 in South Africa.

Within the project, Reutlingen University is leading the cross-location "task force end devices", which is investigating and scientifically preparing the topic of "5G end devices for standalone campus networks". The aim of task force end devices is to answer the following research questions:

To what extent do different 5G end device configurations influence the feasibility of 5G applications in standalone campus networks?

In addition, the 5G4KMU project consortium, in cooperation with the University of Hohenheim, prepared a study on the topic of 'Acceptance of 5G campus networks' (published in April 2021). The study characterises forms of acceptance among different stakeholders and focuses in particular on the acceptance of 5G campus networks by the public.

Examples of our quick checks

In a quick check, the project idea on the topic of 5G is examined in more detail in a feasibility study and joint workshops. An exploring project implements the project idea together with a test environment. First, an appropriate concept is designed and prototypically tested in a test environment.

Applications for a quick check or an exploring project are made using the appropriate application form.

Our project partners

The »Reutlingen Center Industry 4.0« is supported by the teaching and research center of ESB Business School at Reutlingen University where it is integrated into the organisational structure. The core topics of the research work concern the strategies, technologies, procedures and processes in production and logistics systems. The focus is on technical, business management and information technology issues. The increasing use of information and communication technology in the future and the intensified global networking of machinery and plant into decentralised, cyber-physical systems (CPS) under the collective term "Industry 4.0" can thus be addressed.

The scientists at the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) are investigating the requirements and potential of 5G around the topics of production. This includes, for example, the integration and networking of different systems in production (machines, robots, PLCs, cloud services), machine-to machine communication (M2M), cloud edge architectures or digital production images. Fraunhofer IPA supports SMEs from the conception and implementation of their ideas to testing with 5G infrastructure in the test environment in Stuttgart.

At the location of the IPA Project Group for Automation in Medicine and Biotechnology right in the middle of the University Hospital Mannheim, a fully equipped experimental hybrid operating theatre is available as a technology department platform and is a central component of the infrastructure, enabling development and testing in a clinical environment and thus easy transfer of the developments into clinical practice. The development of medical technology solutions and innovative medical processes requires early testing in realistic scenarios. The Mannheim Medical Transfer Center provides industry and research partners with an infrastructure in which new products can be trained in realistic scenarios and process data can be collected for simulation purposes.

The Fraunhofer Institute for Industrial Engineering (IAO) is investigating the possibilities of 5G in the context of cloud-based solutions, especially in the Internet of Things (IoT). The focus is on practical issues as well as challenges, solutions and tests for the development of smart services or smart products. In this context, the importance of new, innovative business models, networking, cloud computing and suitable architectures as well as artificial intelligence play a special role in our activities. In line with these focal points, Fraunhofer IAO would like to make 5G technology accessible to small and medium-sized enterprises. By supporting companies from the conception of intelligent products and services to initial prototype implementations and to their testing in the 5G test environment available for this purpose, ideas can be supported all the way to market launch.

Campus Schwarzwald - Centrum für Digitalisierung, Führung und Nachhaltigkeit Schwarzwald gGmbH operates in close cooperation with the University of Stuttgart and the mechanical engineering and manufacturing industry from the Black Forest region as an innovative networking and education platform. The modern campus building, which opened in autumn 2019, has a 700 m² machine park including a high-tech laboratory directly at the location in Freudenstadt.

As part of the 5G4KMU project, research topics are addressed using the industrial test environment in the field of 5G together with the regional cooperation companies of Campus Schwarzwald and other interested companies.

The focus of the test environment is on the factory/integration level and the digital product image in (special-purpose) mechanical engineering and the manufacturing industry. The digital product image includes, for example, digital industrial engineering, the digital twin, virtual commissioning and the acquisition and needs-based analysis of large amounts of data in an industrial context.

As part of the project, the scientists at the wbk Institute of Production Science at the Karlsruhe Institute of Technology (KIT) are primarily investigating questions that arise within the framework of the digitisation of production driven by 5G in the context of data, machine learning and AI applications. One aspect of wbk's research is human-machine interaction in the context of augmented reality applications and the localisation of operating resources. Further, wbk is researching local production data acquisition without a network infrastructure as well as the derivation of production strategies using intelligent algorithms and the closing of control loops in production.

Your contact person

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/6/csm_Palm_Daniel_2023_06_14_9e3717548b.jpg)